Finding Over $140,000 in Energy Efficiency Rebates for Client’s Efficient Industrial Presses

The Client

Tier 1 automotive supplier to prominent U.S. automotive brands with over $1 billion in annual revenue. This company utilizes advanced plastic-molding and assembly technologies to manufacture over 1 million parts annually, uniquely designed for specific vehicle models.

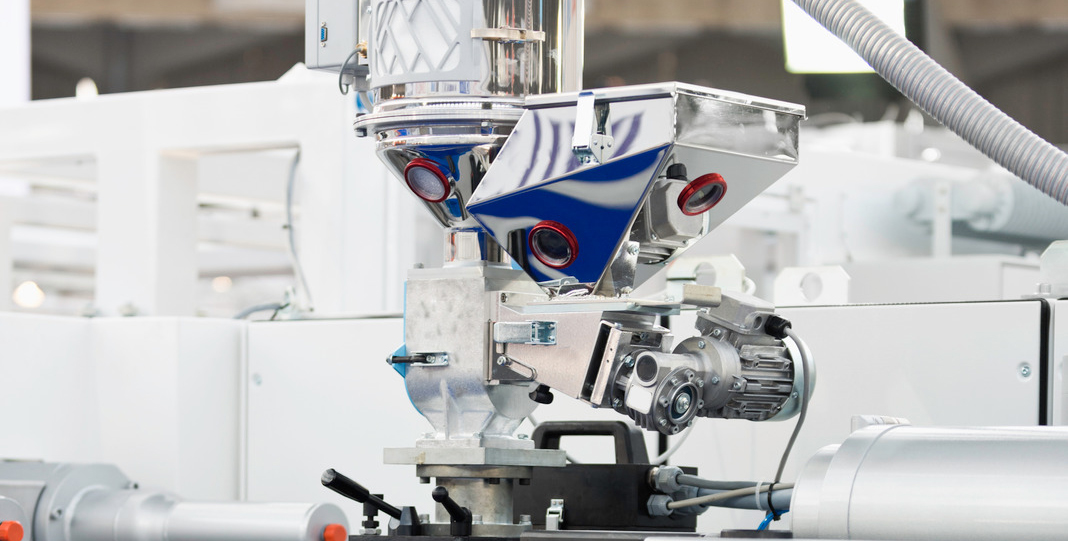

Integral to this company’s process are injection molding machines (IMMs): industrial presses that mold raw materials – such as plastic polymers – into pieces with complex geometries. IMMs can produce large quantities of these pieces with precision and consistency, but they are very expensive and require a lot of energy to function.

The Situation

As part of a major expansion project starting in late 2018 – 2020, the company purchased 13 IMMs capable of clamping forces between 180 tons and 2,500 US tons (1,600 – 23,000 kN). They spent millions of dollars on the machines alone and expected energy costs to increase significantly once production began. The cost and complexity of this project, combined with the company’s substantial operating costs and ever-changing needs, made recuperating any costs a necessity. URA was already contracted to manage the company’s utility spends, so their leadership brought the case to URA’s analysts.

URA’s Solution

URA’s analysts investigated whether the machines could be eligible for energy efficiency equipment rebates through the company’s electric utility. Analysts then collected pictures of each machine’s motor nameplate and coordinated with the vendor to verify crucial efficiency specifications. They determined 10 of the presses were brand new and met efficiency criteria for electric/hydraulic hybrid IMMs.

URA coordinated the collection of all relevant invoices, specification sheets, and completed all the necessary paperwork for the rebate application and applicable bonuses. URA’s analysts then worked with the utility’s program engineers to confirm the accuracy of all calculations and documentation.

URA Results = Client Benefits

In spring of 2020, amidst the Coronavirus pandemic and mandatory lockdowns for businesses, URA’s client received a check for $140,790 dollars from the utility company. This experience convinced the client’s leadership to pursue other energy efficiency opportunities as well as strengthen the partnership with URA to uncover more savings- which they certainly have!

Below are some figures reported by and/or based on the utility’s conclusions for the equipment compared to baseline energy consumption for similar machinery:

- Annual Energy Usage Reduction: 2,485,010.00 kWh

- Annual Energy Cost Savings: $188,860.76

- Incentive Awarded: $140,790.00